Technical expertise driving excellence.

The keys to the success of a Cost/Time development

Which is understandable because if you take the daily cost of the development team and plan to reduce the lead time, the gains on paper are easy to demonstrate.

Same reasoning for the return on investment, the sooner the money comes in from the products sold, the sooner the break-even point will be reached. This explains the management’s enthusiasm for this cost/delay objective.

What risks do you take by implementing development methods whose main objective is cost/time?

You will face 3 main problems:

• An uncontrolled skid of your expenses

• An unknown product availability date

• Uncertain project profitability

Why?

There are two main criteria to consider in this analysis:

1- The interaction between the cost of the product and its development phases.

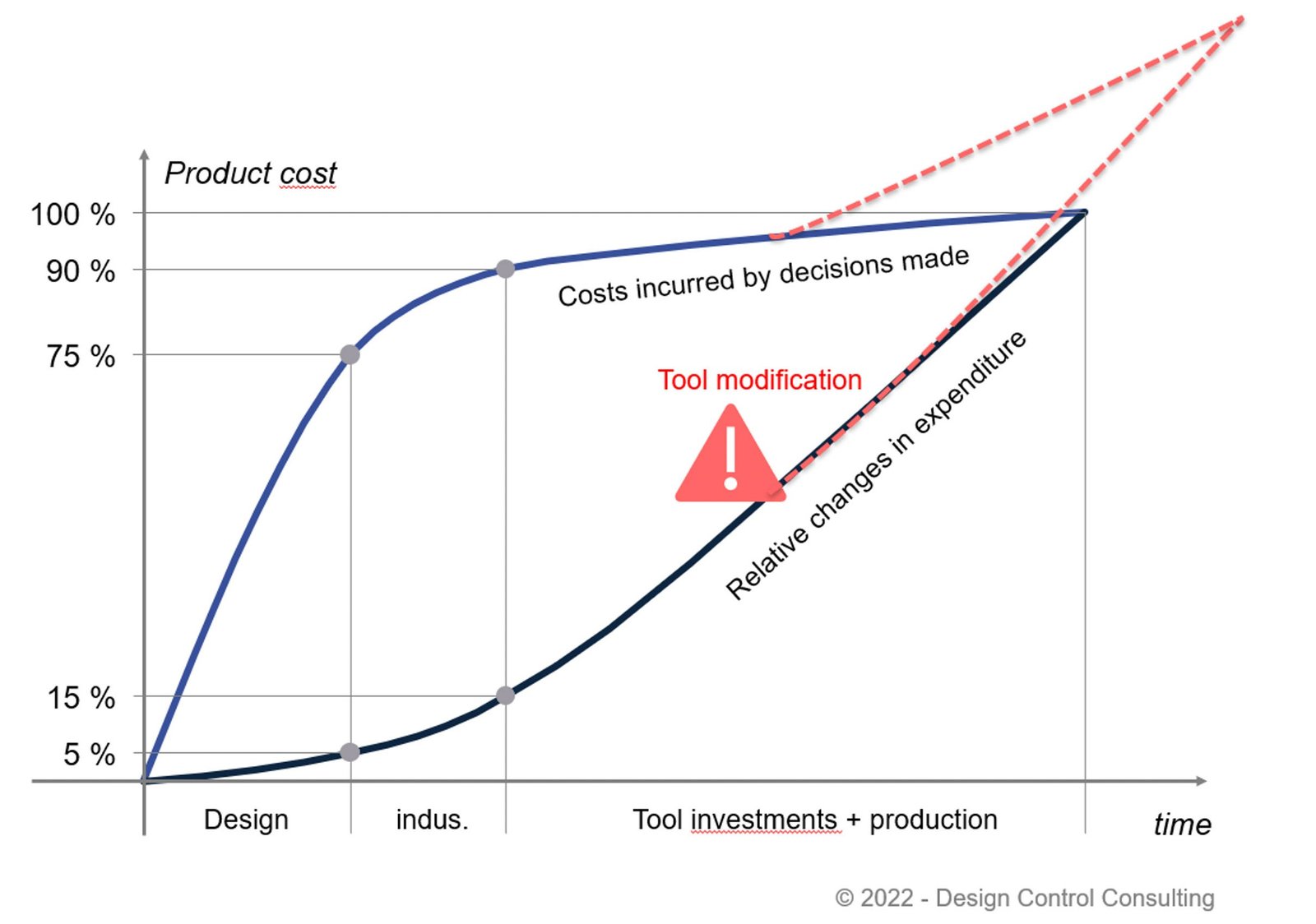

This graph shows the relationship between the expenses incurred at a key moment in the product life cycle with the costs incurred at that same moment.

So, if we apply this analysis to the study phase, we can deduce that 75% of the total cost of the product is determined while it only represents in expenditure realized 5% of the total budget.

For the product industrialization phase, this represents 90% of the total cost of the product for 15% of the total budget.

Consequently, if the product is modified during the investment phase, the cost of the project as well as the cost of the product may escape any economic control, which would be catastrophic in the context of a Design To Cost* or design for an objective cost (CCO).

* The basic financial equation of the DTC concept: Product Selling Price (given by the market) = Product Cost Price + Expected Margin. In this scenario, there is a risk of selling at a loss to maintain market share.

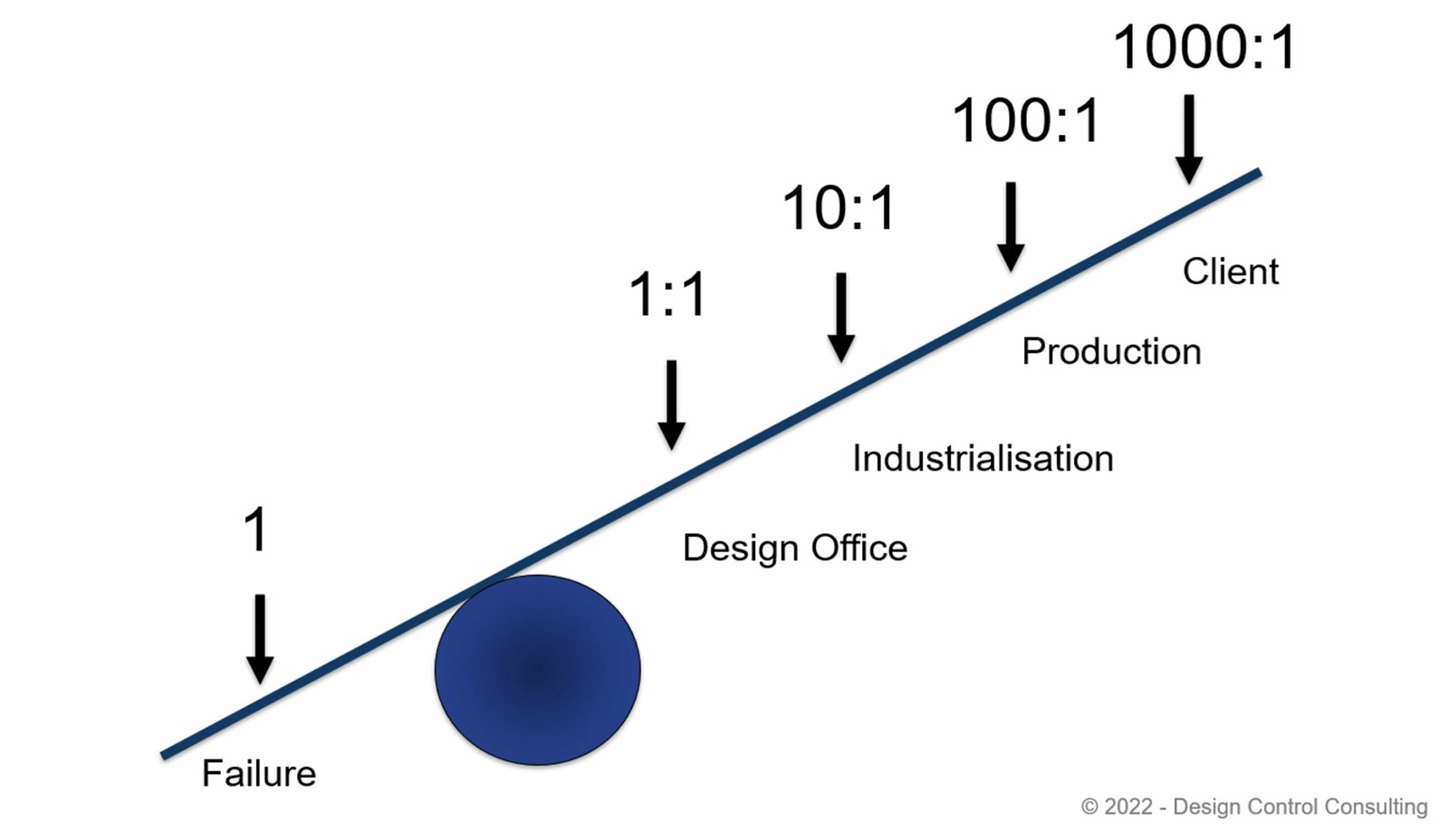

2- The cost of repairing a defect according to its identification phase.

This representation in the form of a scale makes it possible to highlight the financial impact of the correction of a failure according to the phase of the design process where it is discovered.

If the correction of a defect costs 1 Euros when it is carried out at the design office, the same failure will cost 1,000 Euros if it is discovered on a product sold and used by customers.

This report is not to be forgotten, when the decision is taken to launch the industrialization or the production of a development that is not sufficiently accomplished or mastered.

Consequently, there can be no industrial success without positioning quality and compliance with functional requirements ahead of cost/time requirements.

It is through the relevance of your design methods and processes that the control of the robustness and the quality of the product will be established, which allows you to better control the financial risk of a product development centered on a policy of cost/time development.