Technical expertise driving excellence.

Discover the New Version 4.1 of Design Control Power: Optimization and Innovation at Your Fingertips!

We are proud to announce the latest update to our flagship software suite, Design Control Power 4.1.

This release brings significant enhancements and innovative features designed to optimize your design experience and help you reach new heights of quality and efficiency.

Part Aliases

With version 4.1, part aliases become an operational tool, that allows you to replace alphanumeric references from your PLM with more explicit names.

This improvement makes it easier to read and understand the design justification file, providing more tangible information related to the function or nature of the part.

Users can now seamlessly switch between “alias” and “alphanumeric” display according to their preferences, saving time and reducing the risk of errors during design and manufacturing.

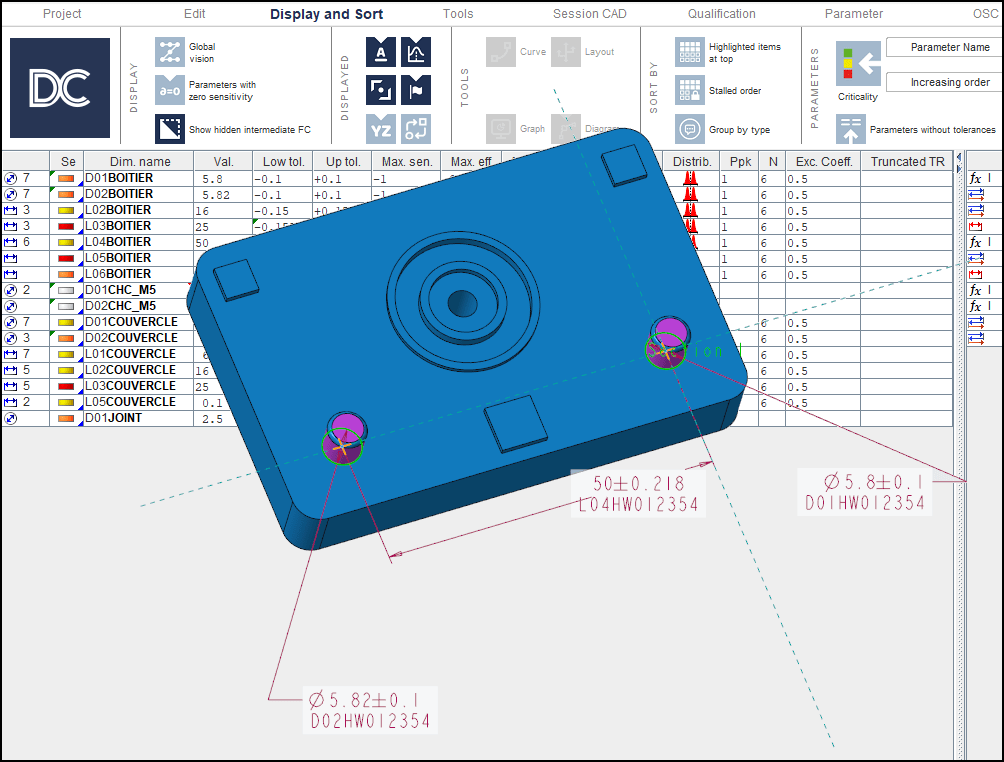

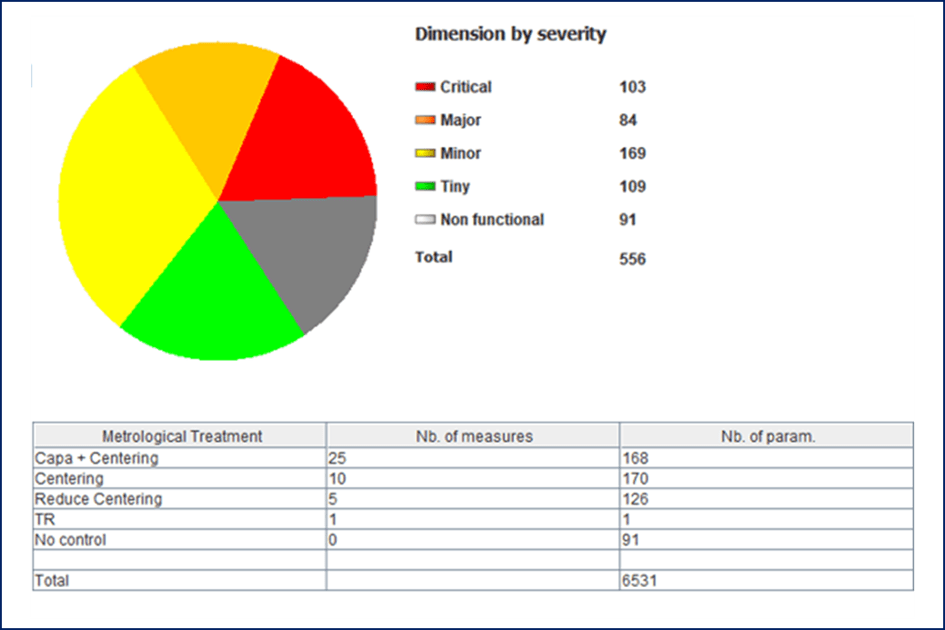

Control plan and qualification

First introduced in version 4.0 for the “Measuring Mastering Helper” suite, this feature is now available with “Quality” licenses.

It allows you to automatically obtain the critical parameters of your products (CTQ / CQA). In version 4.1, calculations and response times have been optimized for faster and more efficient use.

In addition, the control plan and qualification are now integrated with our design history tracking, allowing users to track the evolution between two product versions.

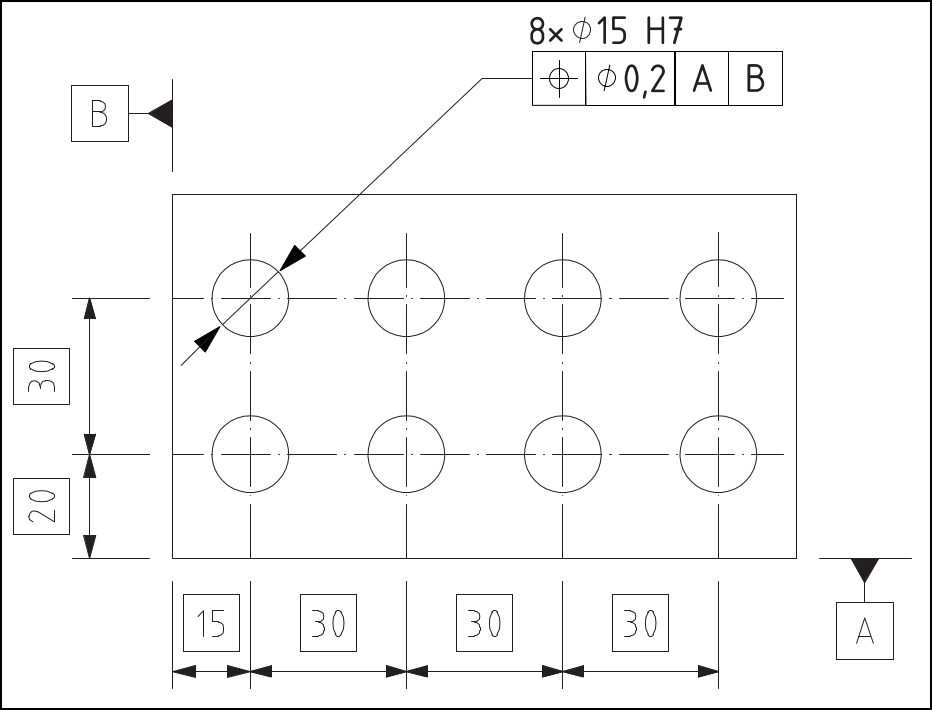

Basic dimension

A specific status has been integrated into the parameter manager for the basic dimension, preventing the assignment of tolerances and ensuring it remains a theoretical reference.

This status is clearly visible in the user interface, with specific fields left blank to avoid any confusion.

It is also transmitted to CAD to ensure the consistency with your 3D models and part definition drawings.

In future versions, this status be further developed to suggest tolerance values for geometric default that are directly linked to the corresponding basic dimensions.

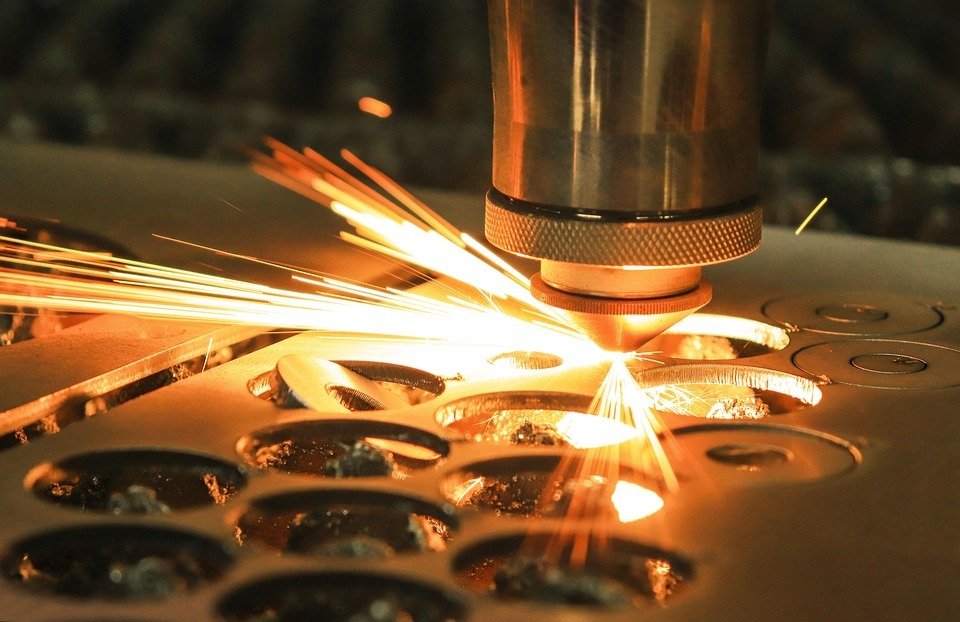

Laser and Plasma Cutting

With this latest version, Design Control Power is now able to automatically propose tolerance ranges for your components obtained by thermal cutting (ISO 9013:2017), complementing the sheet metal capabilities of the software.

This manufacturing technology is in addition to the many others already available in the software (plastic molding, rubber and alloys, cutting, bending, machining, etc.).

We are eager to see how version 4.1 of Design Control Power will simplify and accelerate the generation of your design justification file. Contact us to obtain this version and discover for yourself the benefits it can bring to your business..

Your feedback is valuable to us, so please share your thoughts!